Chapter 4, Part 7 of the Work Health and Safety Regulations 2012

https://www.legislation.sa.gov.au/lz?path=%2FC%2FR%2FWORK%20HEALTH%20AND%20SAFETY%20REGULATIONS%202012

Each year electrical accidents cause injury and death to many South Australian workers. Every year in Australia 30 people are injured or killed as a result of electric shock. Most of these fatalities could have been prevented by the use of a properly installed Residual Current Device (RCD) commonly known as a safety switch.

Electricity does not need to have high voltage to cause electrocution. A voltage as low as 50 volts applied between two parts of the human body, causes a current to flow that can block the electrical signals between the brain and muscles. Although there are many different causes of electrocution, they have one thing in common they could be prevented. Some of the most common causes of electrocution are contact with overhead wires, carrying out maintenance work on live electrical circuits, working with damaged electrical equipment, extension cords, plugs or sockets and unsafe work practices.

Injuries or symptoms that can occur due to contact with electricity include:

- Burns to the skin or internal tissue

- Muscle spasm

- Partial loss of limb function

- Eye damage

- Neurological disorders

- Electrical interference of the heart

- Sudden onset of cardiac arrest

- Respiratory problems

- Unconsciousness

To reduce these incidents a person conducting a business or undertaking (PCBU) needs to identify the electrical hazards in the workplace

and implement control measures.

Division 2 – General Risk Management of the Work Health and Safety Regulations 2012

Risk Management

A person conducting a business or undertaking at a workplace must manage risks to health and safety associated with electrical risks at the workplace.

Example, Electrical risks are associated with the design, construction, installation, protection, maintenance and testing of electrical equipment and electrical installations at a workplace.

Control measures for electrical safety include:

- ensuring competent people are used for electrical work.

- ensuring electrical equipment is maintained in a safe condition by regular inspections

and testing.

Residual Current Devices (RCDs)

RCD means a residual current device as defined in AS/NZS 3760 In-service safety inspection and testing of electrical equipment.

RCDs are effective in reducing the number of serious electrical accidents by monitoring earth leakage. When the RCD detects this leakage it instantly cuts the power before a serious accident occurs. A wide variety of equipment needs RCD protection, for example hand-held power tools like drills and saws, construction site equipment, large mobile tools like electric jack hammers and appliances in wet kitchen areas like kettle, jugs and blenders. To be effective RCDs need correct installations and should be checked and tested every 12 months, however portable RCD units should be tested before the first use of every day.

There are 4 different types of RCDs each with their own purpose: Hardwired (non -portable),

non-portable within-socket RCD on first or selected socket on circuit, portable plug type, portable stand-alone unit.

Portable RCDs are plugged into a power outlet, an appliance is then plugged into the RCD.

Where hardwired protection is not available portable RCDs must be used with hand held appliances and where electrical appliances are in close proximity to water.

Hardwired RCDs or non-portable RCDs are incorporated into a switchboard. They give protection at the source of the electrical current and are attached to different circuits within the board.

Section 165 – Testing of residual current devices

A person with management or control of a workplace must take all reasonable steps to ensure that residual current devices used at the workplace are tested regularly by a competent person to ensure that the devices are operating effectively.

Maximum penalty:

(a) In the case of an individual – $3 600

(b) In the case of a body corporate – $18 000

Expiation fee:

(a) In the case of an individual – $432

(b) In the case of a body corporate – $2 160

The person must keep a record of all testing of a residual current device (other than any testing conducted daily) until the earlier of the following occurs:

(a) the device is next tested;

(b) the device is permanently removed from use.

Maximum penalty:

(a) In the case of an individual – $1 250

(b) In the case of a body corporate – $6 000.

Expiation fee:

(a) In the case of an individual – $144

(b) In the case of a body corporate – $720

Tagging

Once tested tags should be attached in order to identify examined and tested plant. The tag should be durable and posses the following information:

- The date the last exam and test was carried out

- Who carried out the exam and test

- When the next exam is due

Tags must not be metallic or reusable. In some cases as construction and demolition sites colour coded tags may be required.

First Aid

The first thing you must do is disconnect the power supply. Do not touch the victim until you are sure the power supply is turned off. Be careful, especially in wet areas since water conducts electricity.

First aid includes:

- Check for a response and breathing. If necessary, start resuscitating the victim.

- Call triple zero (000) for an ambulance. If you are unsure on resuscitation techniques, the ambulance call-taker will give you easy-to-follow instructions over the telephone, so you can increase the patient’s chances of survival until the ambulance arrives.

- If the breathing is steady and the person is responsive, attend to injuries. Cool the burns and cover with dressings that wont stick. Never put ointments or oils onto burns. If the victim has fallen from a height, only move them if there is no chance of further danger (such as falling objects). Try not to move them unnecessarily in case of spinal injuries.

- Talk calmly and reassuringly to the conscious victim.

Reducing electrical hazards in the workplace

Electricity itself con not be seen and it has no smell. It must be actively sought during inspections and hazard identification. Talking with workers, looking at incident investigation and first aid reports can also help identify possible electrical hazards.

Ways to control hazards in the workplace include:

- Make sure all workers are trained in electrical safety and the correct use of appliances or equipment.

- Install safety switches.

- Arrange for a qualified electrician to regularly test equipment.

- Continually check that electrical leads are not frayed or damaged. If they are damaged, do not use the appliance.

- Install more power points rather than use double adapters or extension leads.

- Keep leads away from walkways or hot surfaces.

- Wear appropriate personal protective equipment such as rubber soled shoes.

- Fit guards or restrictor plates to equipment where appropriate.

- Make sure equipment is fitted with safety valves, water level and pressure gauges where required.

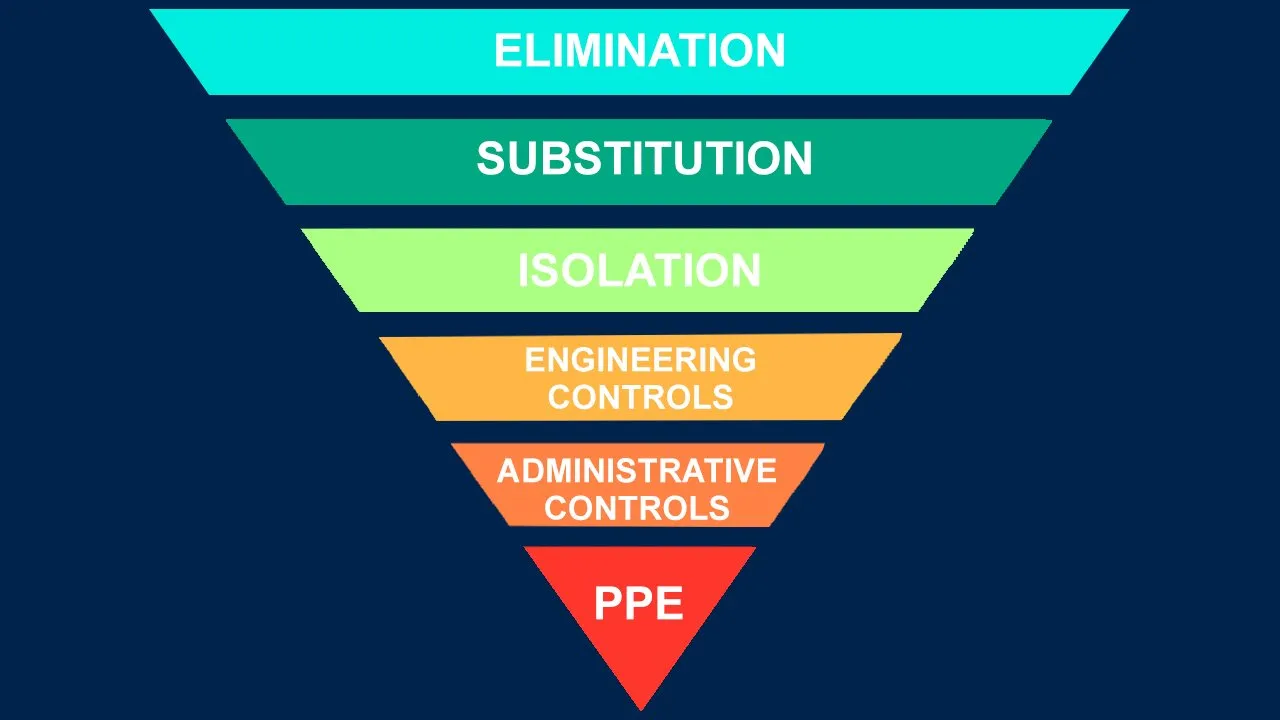

| Hierarchy of Control

Elimination |

|

|

|

| Substitution | |

|

|

| Isolation | |

|

|

|

|

| Engineering | |

|

|

| Administrative | |

|

|

| Personal Protective Equipment | |

|

Australian Standards relevant to working with electricity

AS/NZS 3000-2000 Wiring Rules

AS/NZS 3760-2003 In-Service Safety Inspection and Testing of Electrical Equipment.